Pharmaceutical Quality Control: How XR Visualises Complex Production Processes

Pharmaceutical manufacturing is incredibly precise, complex, and strictly regulated. Ensuring quality and compliance throughout the production process can be challenging, particularly with traditional monitoring methods.

Introduction

Pharmaceutical manufacturing is incredibly precise, complex, and strictly regulated. Ensuring quality and compliance throughout the production process can be challenging, particularly with traditional monitoring methods. This is where Extended Reality (XR) technologies, including Virtual Reality (VR), Augmented Reality (AR), and Mixed Reality (MR), step in, transforming pharmaceutical quality control by providing immersive visualisation and enhanced monitoring capabilities.

XR’s Impact on Pharmaceutical Quality Control

Real-Time Visualization and Enhanced Understanding

XR technology enables visualisation of complex pharmaceutical processes in real-time, turning abstract data and workflows into immersive visual experiences. For instance, AR can overlay real-time sensor data directly onto equipment during operations, allowing technicians to identify anomalies immediately and make informed decisions swiftly.

Immersive Training and Error Reduction

Training new employees on intricate manufacturing procedures is both costly and time-consuming. XR training platforms create realistic simulations of pharmaceutical production lines, allowing employees to experience and practice quality control protocols in safe virtual environments. This approach significantly reduces errors, shortens learning curves, and enhances procedural retention.

Remote Collaboration and Expertise Access

One of XR’s most significant benefits is facilitating remote collaboration. Experts located anywhere globally can virtually "step into" the manufacturing floor, assisting teams through complex quality assurance processes. Real-time XR collaboration tools ensure that knowledge transfer is seamless, improving productivity and reducing downtime.

Practical Applications of XR in Pharmaceutical Manufacturing

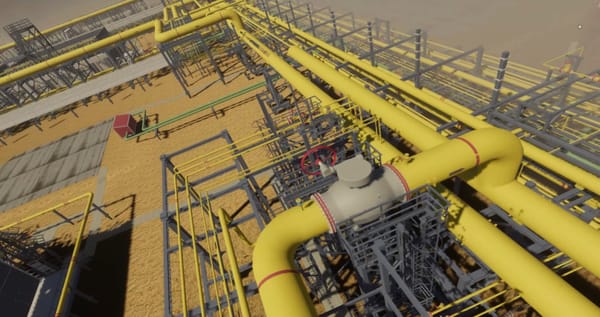

Digital Twins

XR-driven digital twins of pharmaceutical production facilities allow companies to create exact virtual replicas of their physical assets and processes. Digital twins simulate and visualise real-time production data, enabling proactive quality monitoring and predictive maintenance, significantly reducing costs associated with equipment downtime and process errors.

Process Validation and Regulatory Compliance

AR and VR tools provide comprehensive visualization for regulatory compliance and validation processes. XR enables teams to visualise complex documentation, SOPs (Standard Operating Procedures), and validation procedures interactively, simplifying audits and compliance checks.

Hazard and Contamination Prevention

XR solutions can visualize potential contamination pathways, airflow patterns, and hazardous scenarios. Immersive visualisations help workers quickly identify risks and enhance containment strategies, crucial for maintaining sterile environments in pharmaceutical production.

Challenges and Considerations

Despite the significant benefits, adopting XR technology involves considerations around data security, initial investment costs, and integrating XR into existing quality management systems. Companies must strategically assess these factors to maximize the return on investment.

The Future of XR in Pharmaceutical Quality Control

With continuous advancements in XR technology and integration with AI-driven analytics, the pharmaceutical industry's quality control processes will become increasingly predictive, proactive, and precise. Immersive visualisation will shift from being an innovative option to a necessary standard for competitive pharmaceutical manufacturing.

Conclusion

XR technologies are revolutionizing pharmaceutical quality control by offering unmatched visual clarity, real-time monitoring, and collaborative capabilities. The future promises even greater potential as XR becomes deeply embedded within pharmaceutical manufacturing processes.

Want to learn more about how Simulation Creation can help transform your operation ? Fill out the form below to get in touch.