How Virtual Reality is Transforming the Oil and Gas Industry

The oil and gas industry is known for its high-risk environments, complex operations, and the constant need for safety training.

The oil and gas industry is known for its high-risk environments, complex operations, and the constant need for safety training. As technology advances, Virtual Reality (VR) is emerging as a game-changer, providing immersive experiences that enhance training, improve safety, and optimise workflows. From realistic disaster simulations to interactive equipment training, VR is helping companies revolutionise their operations. Let’s explore how VR is making an impact in the oil and gas sector.

1. Enhanced Safety Training with VR

One of the biggest challenges in the oil and gas industry is ensuring worker safety in hazardous conditions. Traditional safety training methods, such as manuals and classroom sessions, often fail to provide hands-on experience. VR changes this by offering fully immersive training environments where employees can practice safety protocols in real-world scenarios without any risk.

Fire and Explosion Simulations

Fires and explosions are among the most catastrophic hazards in the oil and gas sector. VR simulations allow workers to experience these emergencies in a controlled, virtual environment. They can practice evacuation procedures, learn how to use fire suppression equipment, and understand how to respond under pressure—all without the danger of real-life exposure.

Confined Space and High-Risk Area Training

Oil refineries and drilling platforms often require workers to operate in confined spaces or at great heights. VR can simulate these environments, helping workers get familiar with tight spaces, heavy machinery, and emergency exits before stepping onto the actual site. This significantly reduces the risk of accidents and enhances confidence in dealing with challenging situations.

2. Disaster Preparedness and Emergency Response

Oil spills, gas leaks, and blowouts can have devastating consequences. Effective emergency response is crucial to minimising damage and ensuring personnel safety. VR provides a safe and repeatable way to train emergency response teams for various disaster scenarios.

Oil Spill Response Training

Using VR, teams can practice containment and cleanup strategies for oil spills. They can simulate deploying booms, coordinating response teams, and using skimmers—ensuring they are well-prepared for real-life situations without wasting resources.

Gas Leak and Blowout Drills

Gas leaks are highly dangerous due to their potential for explosion and health risks. VR training can simulate different leak scenarios, allowing workers to practice detection, containment, and evacuation protocols in a risk-free setting.

3. Equipment Training and Maintenance

Operating and maintaining complex machinery in the oil and gas industry requires extensive training. VR provides an interactive way for employees to learn how to operate equipment, conduct maintenance, and troubleshoot issues—all without shutting down operations or putting workers at risk.

Hands-On Learning with Virtual Equipment

VR allows employees to interact with digital twins—virtual replicas of real-world equipment. They can practice operating machinery, assembling and disassembling parts, and identifying faults. This reduces the learning curve and minimises costly errors when handling real equipment.

Remote Maintenance Assistance

In remote oil rigs or offshore platforms, access to expert technicians can be limited. VR combined with augmented reality (AR) can enable remote experts to guide on-site workers through maintenance procedures in real-time, improving efficiency and reducing downtime.

4. Workflow Optimisation and Data Visualisation

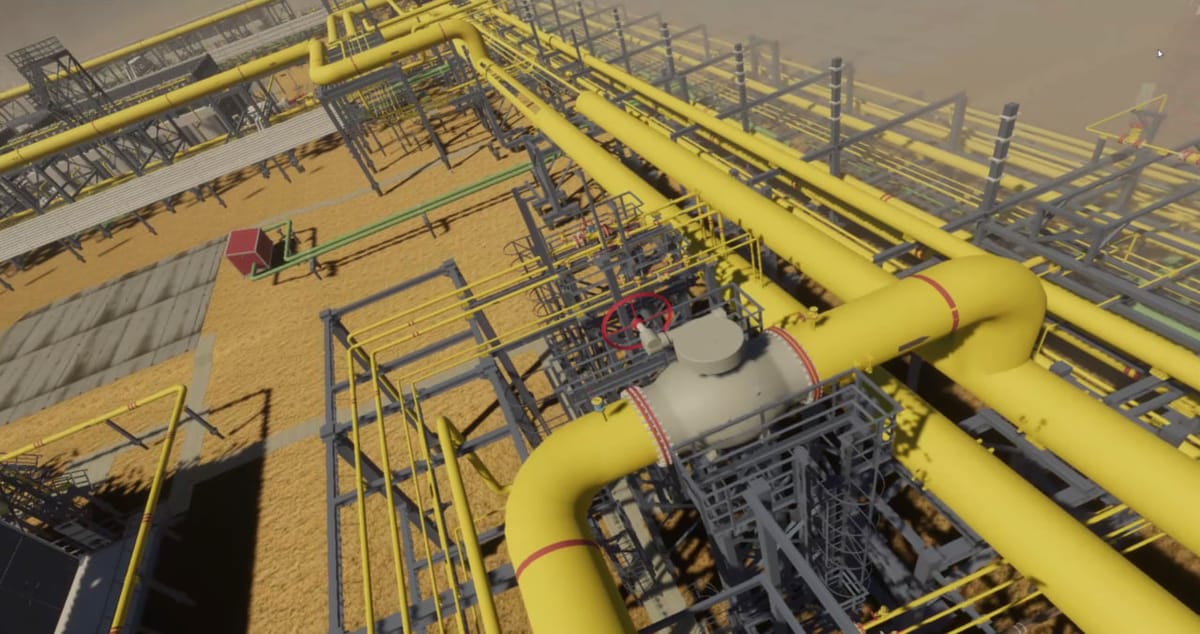

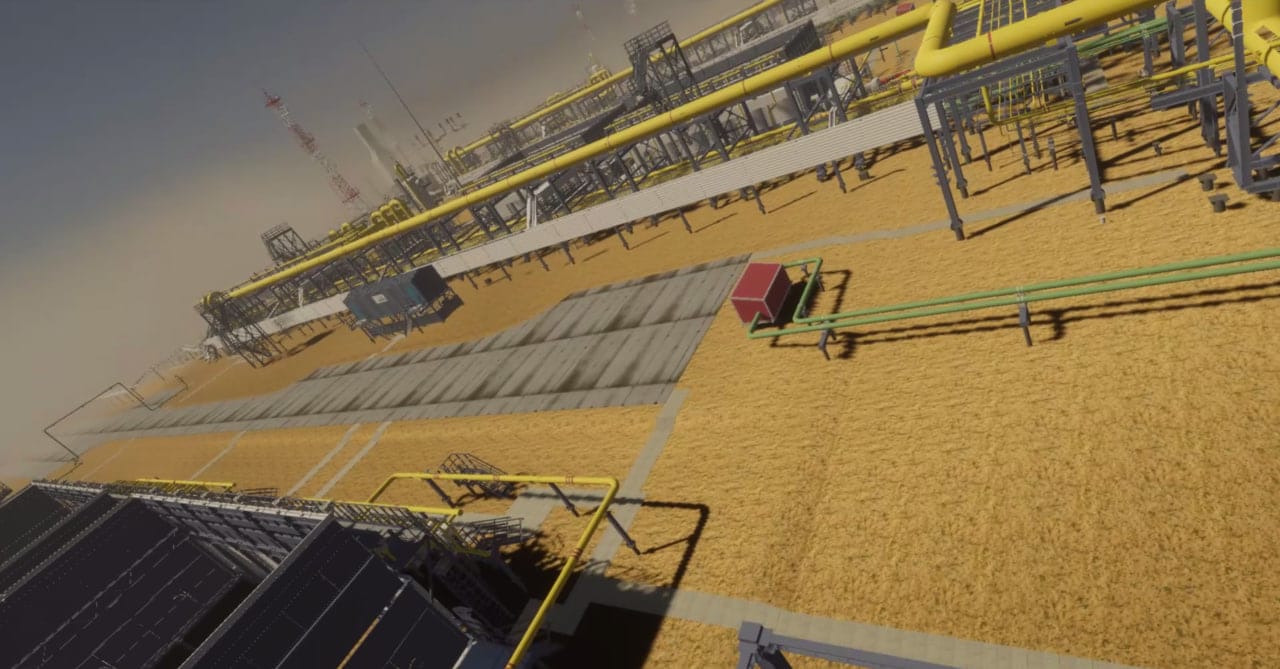

Understanding complex workflows in the oil and gas sector can be challenging. VR allows companies to visualise processes, streamline operations, and improve decision-making through interactive 3D models.

Virtual Facility Walkthroughs

Before construction begins, companies can create VR models of drilling sites, refineries, and pipelines. Engineers and stakeholders can take virtual walkthroughs, identify design flaws, and make necessary adjustments—saving time and costs on real-world modifications.

Real-Time Data Integration

By integrating VR with IoT sensors, companies can visualise real-time data from drilling sites, pipelines, and refineries. Workers can interact with data dashboards in a 3D space, monitor equipment performance, and predict maintenance needs—enhancing overall operational efficiency.

5. Recruitment and Workforce Development

Attracting and retaining skilled workers in the oil and gas industry can be challenging. VR serves as an innovative tool for recruitment and workforce development.

Virtual Job Previews

Prospective employees can experience a day in the life of an oil rig worker, a refinery operator, or a safety inspector through VR. This helps them make informed career decisions and prepares them for the challenges of the industry.

Soft Skills and Team Training

Beyond technical training, VR can enhance communication, leadership, and teamwork skills. Employees can participate in virtual team exercises, conflict resolution scenarios, and cross-functional collaboration simulations.

Final Thoughts

The oil and gas industry is embracing digital transformation, and VR is playing a crucial role in reshaping training, safety, and operations. By leveraging immersive technology, companies can reduce risks, enhance efficiency, and create a more prepared workforce. As VR technology continues to evolve, its applications in the industry will only expand, making operations safer and more productive than ever before.

If you want to discuss how Simulation creation can help with your next project for oil and gas, use the form below to get in touch.