How Simulation Software and Digital Twins Are Revolutionising Global Logistics

In the fast-moving world of global logistics, efficiency is king. Every second shaved off a delivery time, every optimised supply chain route, and every bottleneck eliminated can mean the difference between success and failure.

In the fast-moving world of global logistics, efficiency is king. Every second shaved off a delivery time, every optimized supply chain route, and every bottleneck eliminated can mean the difference between success and failure. Enter simulation software and digital twins—the dynamic duo transforming the way logistics companies operate, plan, and innovate.

What Are Digital Twins and Simulation Software?

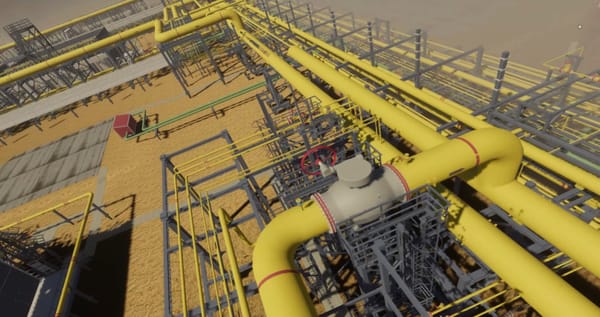

Digital twins are virtual replicas of physical systems—whether that’s a warehouse, a fleet of delivery trucks, or an entire supply chain. These hyper-accurate digital models continuously receive real-time data, allowing businesses to test different scenarios, predict disruptions, and refine their operations without affecting real-world processes.

Simulation software, on the other hand, takes these virtual models a step further by running complex “what-if” scenarios. It allows logistics operators to see how their systems will respond to different conditions—such as supply chain delays, increased demand, or changing fuel costs—before implementing any real-world changes.

Together, these technologies provide unprecedented insight, helping companies fine-tune operations in ways that were previously impossible.

How Digital Twins Are Transforming Global Logistics

1. Optimizing Supply Chains

Supply chains are fragile ecosystems, often at the mercy of unpredictable variables like weather, political disruptions, or global pandemics. Digital twins allow logistics companies to create end-to-end virtual models of their supply chains, identifying inefficiencies and mitigating risks before they cause real-world problems.

For instance, if a major shipping route is suddenly blocked (think the Suez Canal incident), digital twins can quickly simulate alternative routes, considering costs, transit times, and capacity limitations. This proactive approach prevents costly delays and supply shortages.

2. Enhancing Warehouse Efficiency

Modern warehouses are highly automated, with robots, AI-driven sorting systems, and high-speed conveyors. Digital twins provide an opportunity to model these intricate ecosystems, ensuring they run at peak efficiency.

By simulating different layouts, staffing levels, and automation strategies, warehouse operators can determine the most effective ways to move products through their facilities. This minimizes congestion, reduces handling times, and improves overall throughput.

3. Reducing Transportation Costs

Fuel prices, route optimization, and fleet maintenance all play a huge role in logistics profitability. By simulating delivery routes and vehicle loads, companies can cut unnecessary costs and improve sustainability.

For example, a logistics firm using digital twins can analyze different route strategies, assessing factors like road conditions, traffic patterns, and fuel consumption. AI-driven simulation software can suggest the most efficient routes, leading to lower emissions and reduced operational expenses.

4. Improving Last-Mile Delivery

The last mile of delivery—getting a package from a distribution hub to the customer—is one of the most challenging and expensive parts of the logistics process. Simulation software allows companies to test drone delivery routes, autonomous vehicle pathways, and even customer pickup locations to determine the most cost-effective and reliable delivery methods.

Retail giants and logistics firms alike are using digital twins to experiment with different fulfillment strategies, such as micro-warehouses in urban centers or dynamic rerouting based on real-time traffic data.

5. Predicting and Preventing Disruptions

Unexpected disruptions, from extreme weather to labor shortages, can wreak havoc on logistics operations. Digital twins help businesses stay ahead of these challenges by providing real-time analytics and predictive modeling.

By running simulations on different disruption scenarios, companies can prepare contingency plans, ensuring they can adapt quickly and continue delivering products without major setbacks.

The Future of Logistics Is Digital

As global supply chains become more complex, the role of digital twins and simulation software will only grow. Companies that leverage these technologies will gain a significant competitive edge—cutting costs, reducing risks, and improving overall efficiency.

Ready to Transform Your Logistics Operations?

Simulation Creation has already delivered groundbreaking projects in the logistics sector, helping businesses optimize supply chains, enhance warehouse operations, and revolutionize delivery strategies. If you’re looking to stay ahead of the curve, get in touch with us today to discuss your next project.